Page 23 - Higgins Balers Ltd with Austropressen Brochure

P. 23

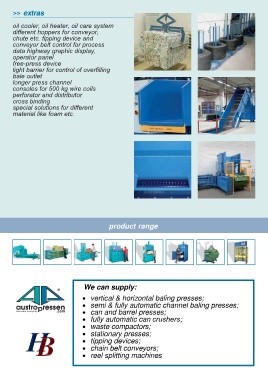

>> extras

H-85-1700 850 96 1700x720 1,8 800x1100 500-800 21200 – 1050x370x340 2x45 2x30 45 15 30 40 430 220 160 – – – 5280 10320 3840 7920 15480 5760 1100021500 8000 – – 5x technische änderungen vorbehalten technical data subject to change oil cooler, oil heater, oil care system

different hoppers for conveyor,

chute etc. tipping device and

H-70-1700 700 80 1700x720 1,8 800x1100 500-700 18500 – 1050x370x340 2x45 2x30 45 45 15 20 30 15 430 325 220 360 – – – – 7800 10320 5280 8640 7920 1170015480 12960 110001625021500 18000 – – 5x conveyor belt control for process www.austropressen.com

data highway graphic display,

operator panel

free-press device

light barrier for control of overfilling

technical data H-55-1400 E-80-1700 550 800 62,5 97 1400x720 1700x1020 1,5 1,7 800x1100 1100x750 400-500 500-600 14600 18400 – 1050x270x340 885x370x340 – 30 2x30 55 45 20 25 30 40 270 250 210 160 – 3500 2940 2240 6480 6000 5040 3840 9720 9000 7560 5760 13500 1050012500 8000 – 4x/5x – 2x 5x – bale outlet

longer press channel

consoles for 500 kg wire coils

perforator and distributor

cross binding

special solutions for different

E-70-1700 700 85 1700x1020 1,7 1100x750 450-600 17500 1050x270x340 – 2x45 2x30 45 15 20 30 410 305 205 5740 4270 2870 9840 7320 4920 7380 1098014760 – – – 4x/5x 2x – material like foam etc.

E-66-1400 660 80 1400x1020 1,4 1100x750 400-600 15500 885x270x340 – 2x30 45 15 20 335 250 4690 3500 8040 6000 12060 9000 – – 4x/5x 2x –

E-55-1400 550 66 1400x1020 1,4 1100x750 400-500 14100 885x270x340 – 45 30 22 15 20 30 335 250 170 4690 3500 2380 8040 6000 4080 9000 12060 6120 – – – 4x/5x 2x –

D-65-1400* 650 87 1400x920 1,3 1000x750 400-600 14400 885x230x330 – 45 30 20 25 235 190 3290 2660 5640 4560 8460 6840 11750 9500 4x 2x – alle maschinen benötigen für ihre optimale leistung eine ölpflege, sowie heizung bzw. kühlung (abhängig vom standort) - to achieve the optimum performance, all the machines need to be equipped with an oil care system, including heating or cooling (depending on location)

D-55-1400* 550 73 1400x920 1,3 1000x750 400-500 13900 885x230x330 – 45 30 22 20 25 35 235 190 135 3290 2660 1890 5640 4560 3240 8460 6840 11750 9500 6750 4x 2x – product range

D-48-1400* 480 64 1400x920 1,3 1000x750 350-500 13500 885x230x330 885x370x240 45 30 22 15 20 30 315 235 160 4410 3290 2240 7560 5640 3840 8460 11340 4860 5760 – – – 4x 2x 4x * materialabhängig bei einer ballenlänge von 1200mm - depending on material for a bale length of 1200mm ** abmasse mit zusatzbindung auf anforderung - dimensions with additional binding on request kanalballenpressen channel baling presses

technische daten D-42-1400* 420 kN 56 N/cm 2 1400x920 mm 1,3 m 3 1000x750 mm 350-400 kg 12900 kg 885x230x330 cm 885x370x240 cm 30 22 kW 12 20 sec. 390 235 m 3 /h 5460 3290 kg/h 9360 5640 kg/h 14040 8460 kg/h – – kg/h 4x 2x 3x vertical & horizontal baling presses;

We can supply:

can and barrel presses;

presskraft pressure force spezifischer pressdruck specific pressure force füllöffnung (b x l) loading aperture (w x l) füllvolumen filling volume ballenformat (b x h) bale size (w x h) ballengewicht** bale weight** maschinengewicht total weight abmasse vertikal (l x b x h) dimensions vertical (l x w x h) abmasse horizontal (l x b x h) dimensions horizontal (l x w x h) antrieb 400V motor 400V zyklus leerlauf open-circuited time theoretische leistung theoretic full capacity pressenleistung 20kg/m 3 press performance 20kg/m 3 pressenleistung 40kg/m 3 press performance 40kg/m 3 pressenleistung 60kg/m 3 press performance 60kg/m 3 pressenleistung 100kg/m 3 press performance 100kg/m 3 vertikale bindung vertical binding zusätzliche horizontale bindung*** additional horizontal binding*** conform/conformity/conformité horizontale bindung horizontal binding semi & fully automatic channel baling presses; D

fully automatic can crushers;

waste compactors;

E

stationary presses;

H

tipping devices;

chain belt conveyors;

reel splitting machines